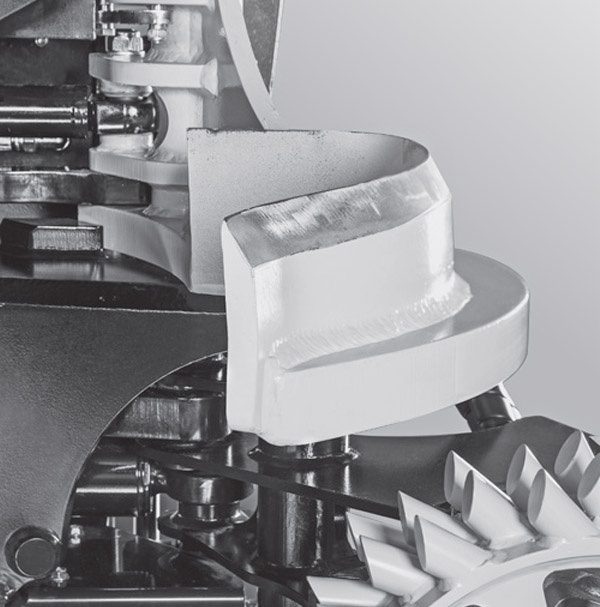

TH65 EUCA

FOR OPTIMIZED HARVESTING AND DEBARKING.

The Logset TH65 Euca harvester head has been developed in South America with a variety of eucalyptus species and under various weather and soil conditions. The 2nd generation Euca head is a result of more than 1500 hours of pilot runs in Brazil with a prototype head. During and between the tests, a variety of components and their combinations were tested in the head, to find the match for optimized debarking and high productivity.

technologies

technologies

DEsigned TO LAST

All Logset Euca heads are welded and assembled in Finland. We take pride in the welding work and the flawless machining that provides the basis for this high-quality equipment. The harvester heads are built using the best wear resistant steel. We have records of several heads passing the 20000 hours milestone, by following our scheduled maintenance program.

A versatile choice

Logset Euca heads are durable and versatile. Their debarking capability is remarkable due to a state of the art three roller concept and specific Euca profile debarking knives. A Logset Euca head can be mounted to work as a processor head or as a conventional felling and cut-to-length harvester.

Maximum felling-/cutting diameter

65 cm

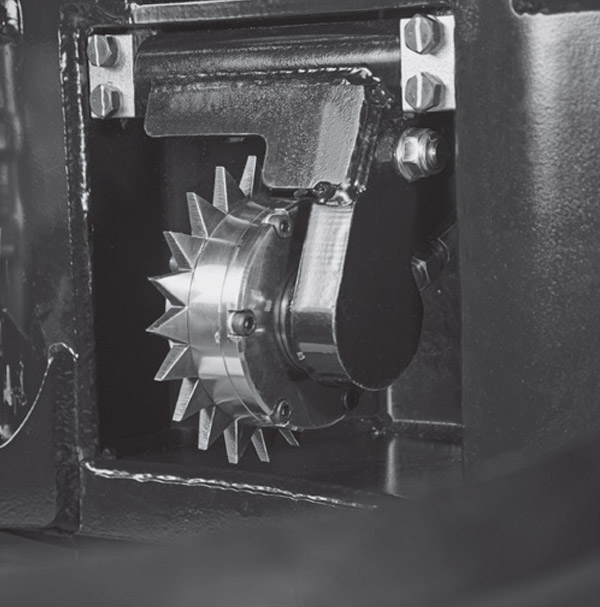

feeding wheel safeguard

The feeding wheel safety guard is as a standard equipment to protect the harvester head from rocky ground, for example when lowered down. The feeding roller model is optional.

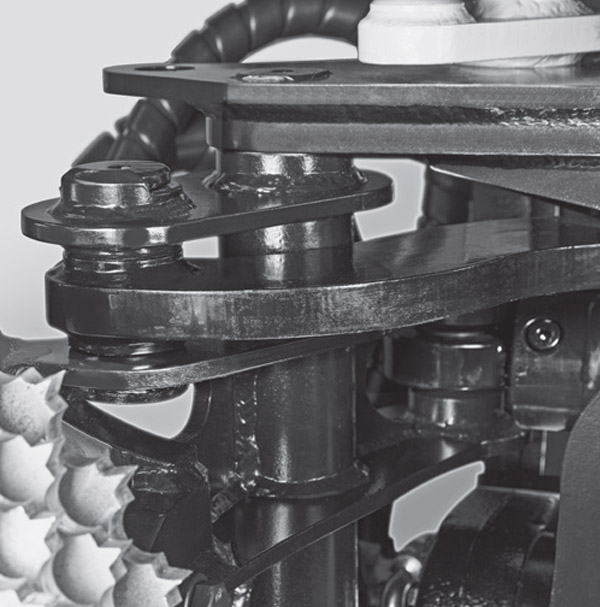

Length Measuring device

The length measuring device is firmly attached to the harvester head frame. Choose the measuring wheel model that suits your needs.

Reaction rod

The reaction rods in the feeder arms centres the woods inside the harvester head and ensures that the stem remains at the bottom of the harvester head even during a possible feeding reversal step.

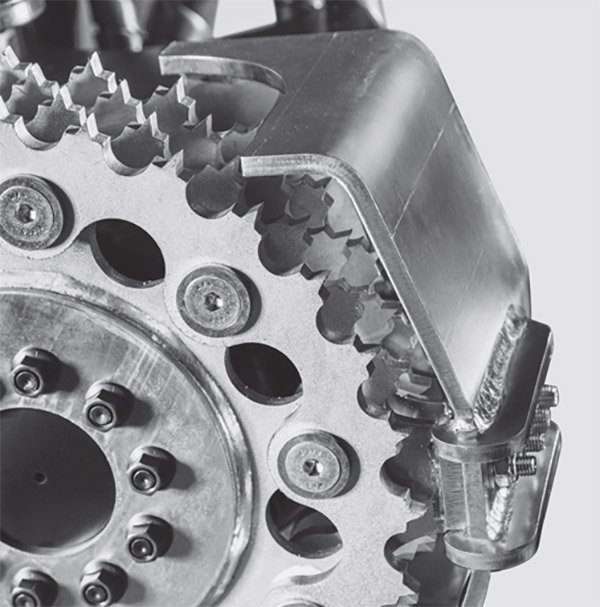

delimbing knives

Robust delimbing knives are optimized for average stem size and them are lightly delimbing large, branched conifers for example.

rear delimbing knives pin

The sturdy housing structure connects both the fastening pins for the rear and front delimbing knives. The service life of the pins is long. The locking nut on the pin keeps the whole package together.

TH65 EUCA

in a nutshell

tech specs

| Width – head open | 1 590 mm (62.6″) |

| Width – head closed | 1 200 mm (47.2″) |

| Height to top knife | 1 380 mm (54.3″) |

| Height with rotator and link | 1 900 mm (74.8″) |

| Weight with rotator and link | 1 300 kg (2860 lbs) |

| Max. felling / cutting diameter | 720 mm (28.3″) |

| Saw bar | 820 mm (32.3″) |

| Saw unit | SuperCut 100S |

| Saw motor | Parker/Bucher |

| Saw chain tensioning | Automatic |

| Chain oil tank volume | 8 l (2.1 US gal) |

| Max pressure | 280 bar (4 061 PSI) |

| Flow required for optimal production | 200 l/min (52.8 US gal/min) |

| Valve block | Purpose built manifold |

| Hydraulic motors – feeding arms | 680/820 cm³ |

| Hydraulic motors – chassis | 315/400 cm³ |

| Number of hydraulic motors | 4 pcs |

| Feeding speed, 300 l/min | 6,0/4,7 m/s (19.7/15.4 ft/s) |

| Max opening – feeding wheels | 630 mm (24.8″) |

| Max opening – upper knives | 680 mm (26.8″) |

| Max opening – rear knives | 750 mm (29.5″) |

| Delimbing diameter tip-to-tip | 450 mm (17.7″) |

| Number of static knives | 2 pcs |

| Number of movable knives | 4 pcs |

| Max tilt angle | 140º |

| Options: | Indexator AV12S, H122 BBR 15H |

| Device: | LOGSET TOC-MD 2 |

| Wheeled base | 14-18 t (30860 – 39680 lbs) |

| Tracked base | 16-20 t (35270 – 44090 lbs) |

Contact your local dealer for more information about options.